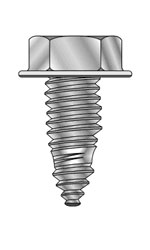

METAL THREAD FORMING

At ITW Shakeproof Industrial, we have created numerous state-of-the-art screw designs. These include products such as Taptite®, Tap/R®, and GX™ Self Extruding that are now standards in the construction industry.

The innovative WERCS Technology we have developed is once again transforming the industry in the design and manufacturing of threaded products and solutions. This technology enables our engineers to design exceptional quality thread geometries to handle the most challenging applications. Our highly innovative selection of threaded products for metal applications – the Tap/R and Taptite – are set to solve your most demanding design requirements..

As a leader among thread forming screw manufacturers, we offer the following types of screws:

- Plastite

- Taptite

- Torx

- Torx Plus

- ACR II

- Quadrex

- MAThread

- PSD

Threaded Fasteners

Mechanical fasteners that are replaceable and removable usually rely on mating threads to generate a dependable, strong assembly. The tightness and reliability of a threaded assembly depends largely on the tension and friction of the assembly.

Friction

Friction happens at the place where the mating threads come together, where the bearing surface under the screw head touches the work surface, and also, if a nut is included in the assembly, where the work surface bottom contacts the upper surface of the nut. Lock and bearing washers can enhance surface friction.

Tension

When torque is applied, screw threads naturally tend to slide even after the screw head leans against the work surface. These fasteners, whether screw or bolt are stretched. When 60,000 PSI is applied to a steel bolt or screw, it will lengthen approximately 0.002 inches per inch of effective length.

Compression is applied to components of the screw head and between any nut in the assembly and the screw. After stress is applied to these materials, they tend to return to their original form. Components experiencing compression, naturally start to expand after the compression is released. Screw that are extended, naturally start to contract in the same manner, just like a spring. Tension can be increased with the addition of washers, such as spring and conical washers, and combinations of these. Through Sems, they can be preassembled to screws.

The level of friction and tension produced in an assembly is initially determined largely by the amount of torque or twisting force that may be imposed on a threaded fastener without stripping the mating threads. The thickness and characteristics of the material involved and how the mating threads are manufactured determines this in part. We present the fasteners in our catalog in this manner, including thread rolling screws – metal and stainless steel.

Quality

At ITW Shakeproof Industrial, our goal is to provide highly cost-effective and exceptional quality fasteners and related components that match the requirements of industry, customers, and government regulations, and to deliver these products in a timely and reliable manner. We are committed to carrying out all of our business practices in an ethical manner that keeps your trust and is so important for successful supplier/customer relationships.

Our team, at every level of our organization are dedicated to providing top quality excellence – from design, to manufacturing, to supply of our fasteners and components. As part of our commitment is an ongoing effort to improve in all aspects of our operations and products. At ITW, our goal is to produce value and enhance the operating efficiencies of our customers.

Get Metal Thread Forming Screw Options

For more information about the sheet metal thread forming and stainless steel thread forming screws we offer, give us a call today at 920.261.2652. Otherwise send us a message or request a quote using our contact form.