LIGHT DUTY

STAMPED NUTS

Shaft Retainers have been a standard product line at ITW Shakeproof for many years. Industry standards such as Internal Tooth, External Tooth, and Wide Rim Slotted Tooth retainers were designed to hold securely on the circumference of a shaft. Through the addition of ITW Powertrain’s Light Duty Stamping products, ITW Shakeproof has expanded its Shaft Retainer offering. Developed for both the Consumer and Industrial markets, the Push on Bolt & Hat Retainers, Hex Flange Speed Nuts, and Self-Threading Locknuts completes ITW’s offering of the Crest product line.

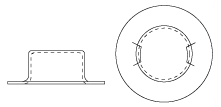

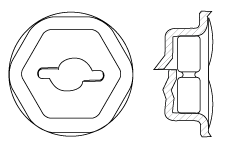

Push-on Bolt Retainer

Use: In assembly applications when screws or bolts need to be retained in position before a nut is positioned and tightened.

Advantages:

-

- Retainer slips onto screws or bolts with minimal effort.

- The screw or bolt is retained tightly and will not push out of the hole when the nut is started.

- Use where appearance warrants that teeth be hidden.

Push-on Fasteners

Studs and Rods – The design and workmanship of the stud or rod is critical for the successful application of Push-On Fasteners.

The following are design requirements:

-

- The stud/rods must be to size and round within a tolerance of ±.0025 inch (.06mm). Care must be taken if the shaft is prepared using a shearing process, as out-of-round conditions can occur.

- The material must not have a hardness of greater than 78 on 30T scale. If the stud/rod is too hard the teeth will not bite into the material.

- The stud/rod should have a lead in angle or chamfer. Sharp edges with burrs can prevent proper functioning of the fastener.

- The minimum pull-off loads listed are static load tests performed under laboratory conditions on metal shafts that meet the above conditions. You may see variations in performance in your application.

Application Tips:

-

- Fixtures should be used to apply the Push–On Fasteners.

- The Fasteners should be presented squarely to the stud or rod; crooked application can affect the performance of the fastener.

- Hat Push-On Fasteners should be applied with a load on the top of the hat, avoid applying a load to the brim of the hat.

- When installing “P” type fasteners, use a fixture that pushes squarely on the OD but avoids interfering with the petals of the Fastener.

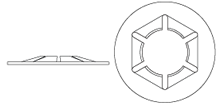

Push-on Hat Retainer: The design and workmanship of the stud or rod is critical for the successful application of Push-On Fasteners.

Advantages:

-

- ITW Push-On-Fasteners eliminated costly secondary operations such as notching, threading or drilling.

- They are designed to hold components on plain round shafts, rods or axles.

- They can be quickly assembled in the field on a shaft or stud, making them ideal for products which are shipped knock-down.

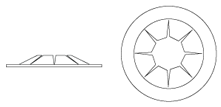

Push-on Retainer Fastener:

Advantages:

-

- ITW Push-On-Fasteners eliminated costly secondary operations such as notching, threading or drilling.

- They are designed to hold components on plain round shafts, rods or axles.

- They can be quickly assembled in the field on a shaft or stud, making them ideal for products which are shipped knock-down.

Self-Threading Locknuts and Washers

Studs and Rods – The design and workmanship of the stud or rod is critical for the successful application of Self- Threading Fasteners.

The following are design requirements:

-

- The stud should have a chamfer to help start the fastener, as per the sketch on this page.

- Metal studs must be to size and round within a tolerance of ± .0025 (.06mm).

- Metal studs must not have a hardness of greater than 80 on the Rockwell B scale.

Self-Threading Locknuts and Washers

Advantages:

-

- ITW Self-Threading Locknuts and Washers provide savings by eliminating costly operations such as threading, grooving, cross drilling and other secondary operations.

- The integrated sure-locking action provides resistance to vibration and eliminates the problem of potential back-off.

- Elimination of cross-threading potential enables faster assembly.

- The integral base on the washer style spans large clearance holes.

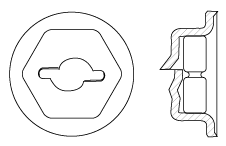

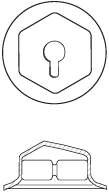

Hex Flange Speed Nut

Regular and Wavy Washer Locknut Eliminates Back-Off:

-

- Locking action eliminates back-off due to vibratory and/or thermal stress.

- Spring forces are exerted upward against bolt threads and downward against the assembly.

- Spring forces are exerted inward, gripping the root of the bolt thread.

- Locknuts may be removed and reused as long as the thread engaging portion has not been flattened by excessive tightening.

Hex-Flang Speed Nut

Advantages:

-

- The ITW Locknut is available in Regular style or Wavy style.

- The Wavy Washer Locknut adds a faceted edge which gives increased resilient “Belleville” locking action when compressed.

- A one-piece ITW Washer Locknut combines the functions of an ordinary Hex Nut, Lock Washer, and Flat Washer.

- There is only one fastener to handle on the assembly line thus, saving time and reducing labor cost with only one fastener to inventory.

- Large clearance holes may be covered by selecting the appropriate washer base.