BOSSCREW™ FASTENERS

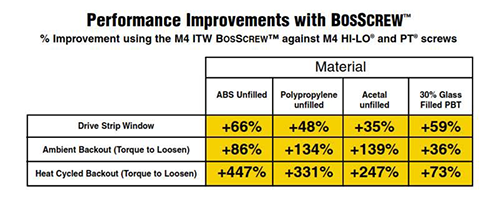

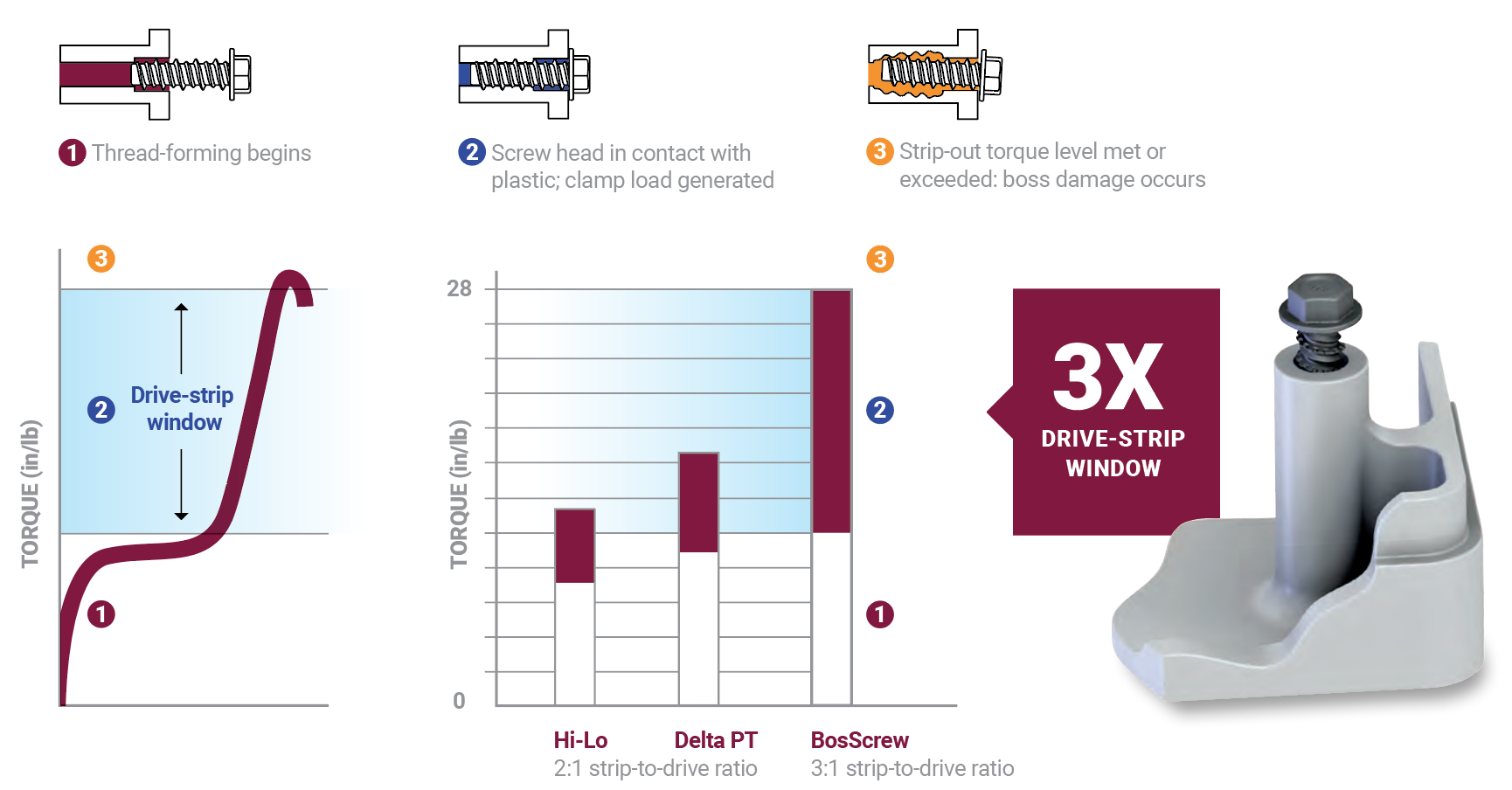

The ITW Shakeproof BosScrew™ is the only screw engineered to not loosen in plastic applications. Its unique thread form, designed with the patented WERCS® technology, works directly with the creeping aspect of plastic to interlock with the boss. The BosScrew™ utilizes standard head diameters and has the highest drive-to-strip ratio in the industry. This is the maximum performance fastener for most plastic applications. Time, temperature, and vibration only strengthen the joint.

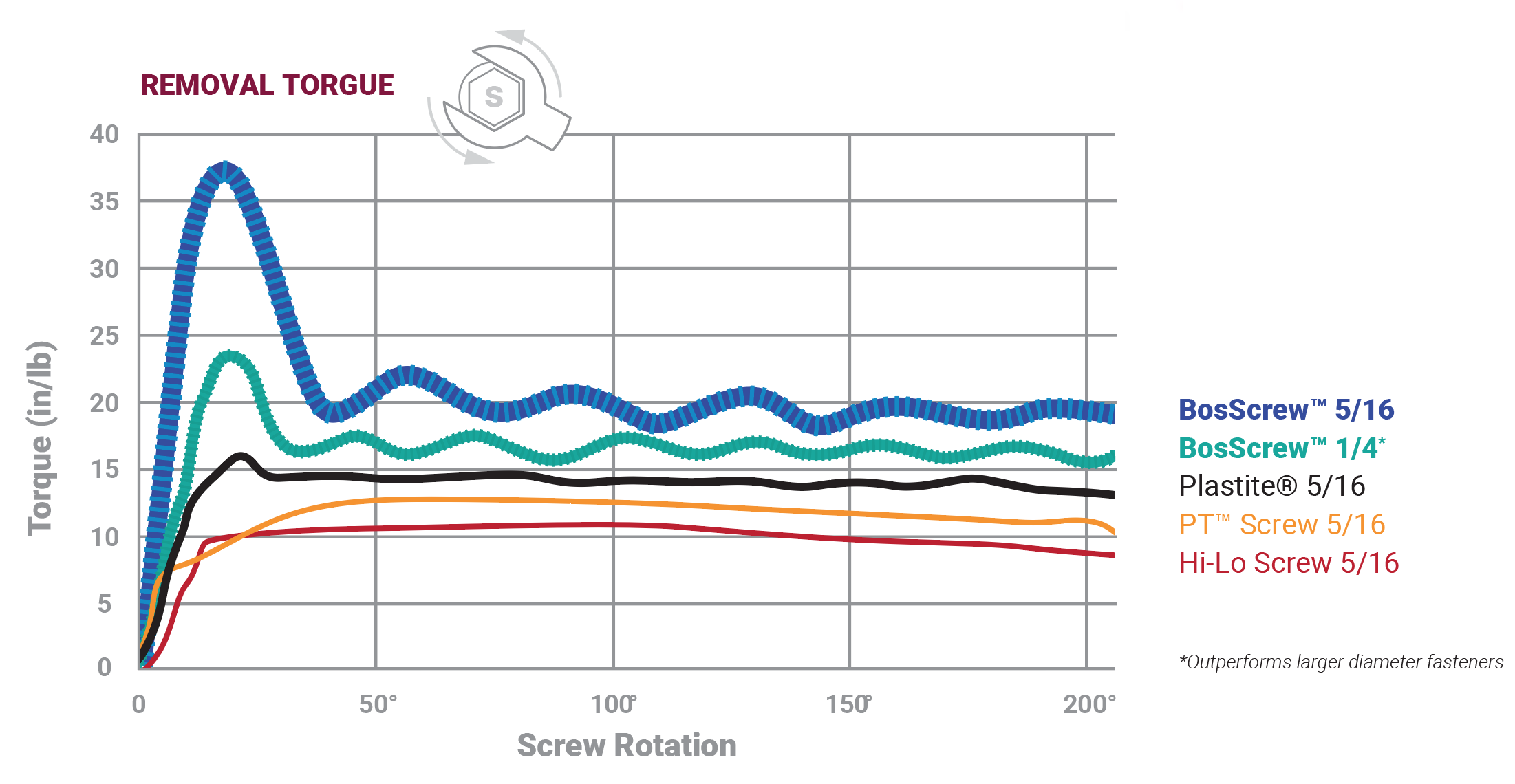

- Best-in-class removal torque

- Dramatically advances fastening performance

- Increases manufacturing efficiency

- Reduces overall installed cost

The BosScrew™ Benefit:

- Reduces assembly components – no more inserts

- Permits the design of shorter bosses – saves material

- No spring components needed in the joint

- Savings in service issues due to fasteners

- Available in a variety of sizes and head styles

Available Features:

- SEMS – add a washer under the head to span larger holes, protect fragile surfaces, and distribute load.

WERCS® Technology:

- ITW’s new WERCS® Technology is revolutionizing the design and manufacturing of threaded products. This technology allows the formation of unique geometries on the thread. Utilizing the WERCS® Technology, ITW has developed a suite or platform of innovative threaded products — products designed to dramatically advance fastening performance, increase manufacturing efficiency and reduce overall installed cost.

MAXIMIZED DRIVE-STRIP WINDOW

BosScrew is the maximum performance fastener for most plastic applications. The unique thread geometry prevents slipping for the largest drive-strip in the industry.

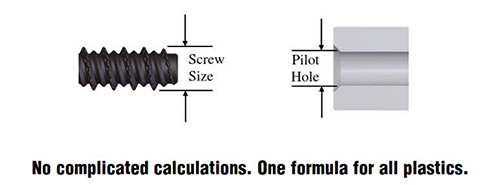

| Typical Mean Pilot Hole | ||

|---|---|---|

| Screw Size | Inches (in.) | Millimeters (mm) |

| #4 | 0.09 | 2.3 |

| M3 | 0,093 | 2.37 |

| #6 | 0.122 | 3.1 |

| M3.5 | 0.122 | 3.1 |

| #8 | 0.132 | 3.36 |

| #10 | 0.154 | 3.92 |

| M4 | 0.132 | 3.5 |

| M5 | 0.154 | 3.9 |

| M5.7 | 0.17 | 4.32 |

| M6 | 0.186 | 4.8 |

| 1/4 | 0.21 | 5.33 |

| M6.3 | 0.209 | 5.31 |

| M8 | 0.248 | 6.3 |

| 5/16 | 0.265 | 6.73 |

| 3/8 | 0.286 | 7.27 |

* Approved recommendations with Acetal Nylon ABS and PBT or equivilant materials