HI-COLLAR

LOCK WASHER

When washers are used with bolts and nuts for industrial applications, one potential risk is the washer loosening from its assembly. Various forces present at the joint may cause this loosening to occur. However, vibrational forces are a common reason for a washer coming loose. Hi-collar lock washers are commonly used to negate the forces that cause washer loosening and prevent failure of an assembly under high torque.

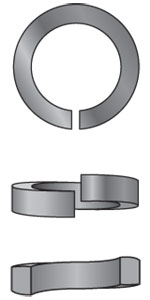

A hi-collar helical spring lock washer has a smaller outside diameter (O.D.) than some other types of washers, allowing it to function in confined spaces. At the same time, these washers have a high thickness that maintains their locking capability. The hi-collar lock washer is ideal for use in conjunction with a socket head cap screw in which clearance is limited.

Function of High Collar Lock Washers

Since these washers have smaller O.D.s than conventional split lock washers, they fit conveniently underneath socket head cap screws. During the tightening of a screw, the hi-collar lock washer flattens, adding tension to the joint, which prevents vibration-induced loosening of the washer. The hardened split ring of these washers has a helical shape which produces a spring force between the fastener and its mating surface. This produces friction and rotational resistance.

If you are looking for high collar lock washers for your manufacturing or field applications, our team is here to help. We have the knowledge and experience to provide recommendations about the optimum washers for your applications. Contact us today to learn about our high collar washer options.