DESIGN GUIDE

Tips for investigating a Fastener Problem:

Get as much information as possible:

-

- Where and how are the parts used?

- Have you bought these parts for a long time?

- Are you the sole customer of this part?

- Request samples of failed parts

- Are unused parts available from the same lot? If yes, request some.

- How many parts are used in the assembly?

- Is there any pattern to the failures – for example, are they failing in a single location?

- What type of driver is being used?

- What torque value is being used to install the parts?

- Request pictures of failed parts and the assembly

- If possible, allow the supplier to visit and observe the problem first-hand.

- How best would you describe the problem?

- Has anything recently changed or something unique occurred?

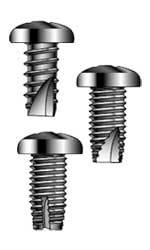

Field Ready™

Tunable torque design allows screws to be shipped in the “Field Ready” position.