TAP/R® THREAD ROLLING SCREWS

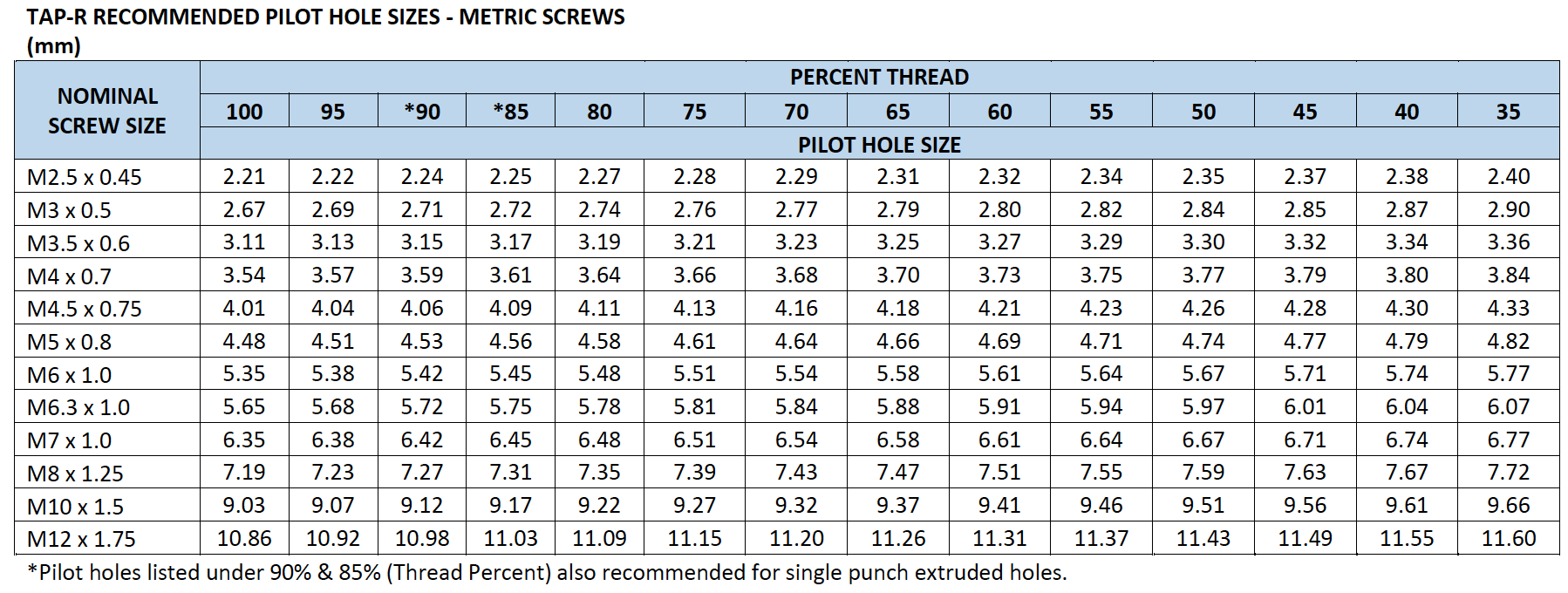

Tap/R fasteners use a shank in the graduated thread rolling area to roll their own perfect mating threads in an un-threaded pilot hole. The tapered point of these thread roll forming fasteners easily locates the pilot hole and eliminates cross-threading in existing holes. The partial threads on the shank form threads in the whole during the initial drive. Full threads complete the screw and provide perfect engagement to finish the drive.

Advantages:

These thread rolling screws provide a number of advantages, including:

-

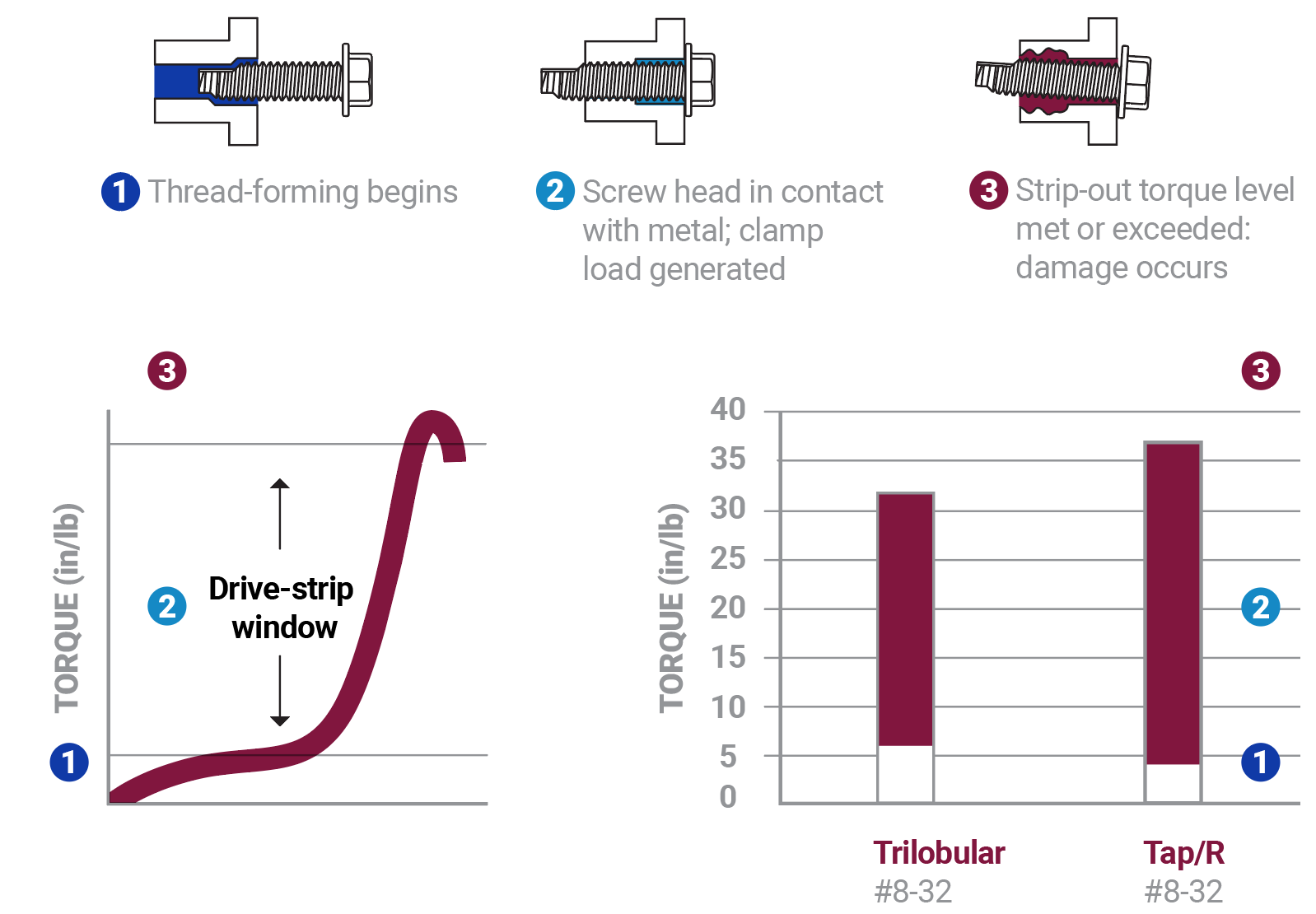

- REDUCE DRIVING TORQUE and increase stripping torque.

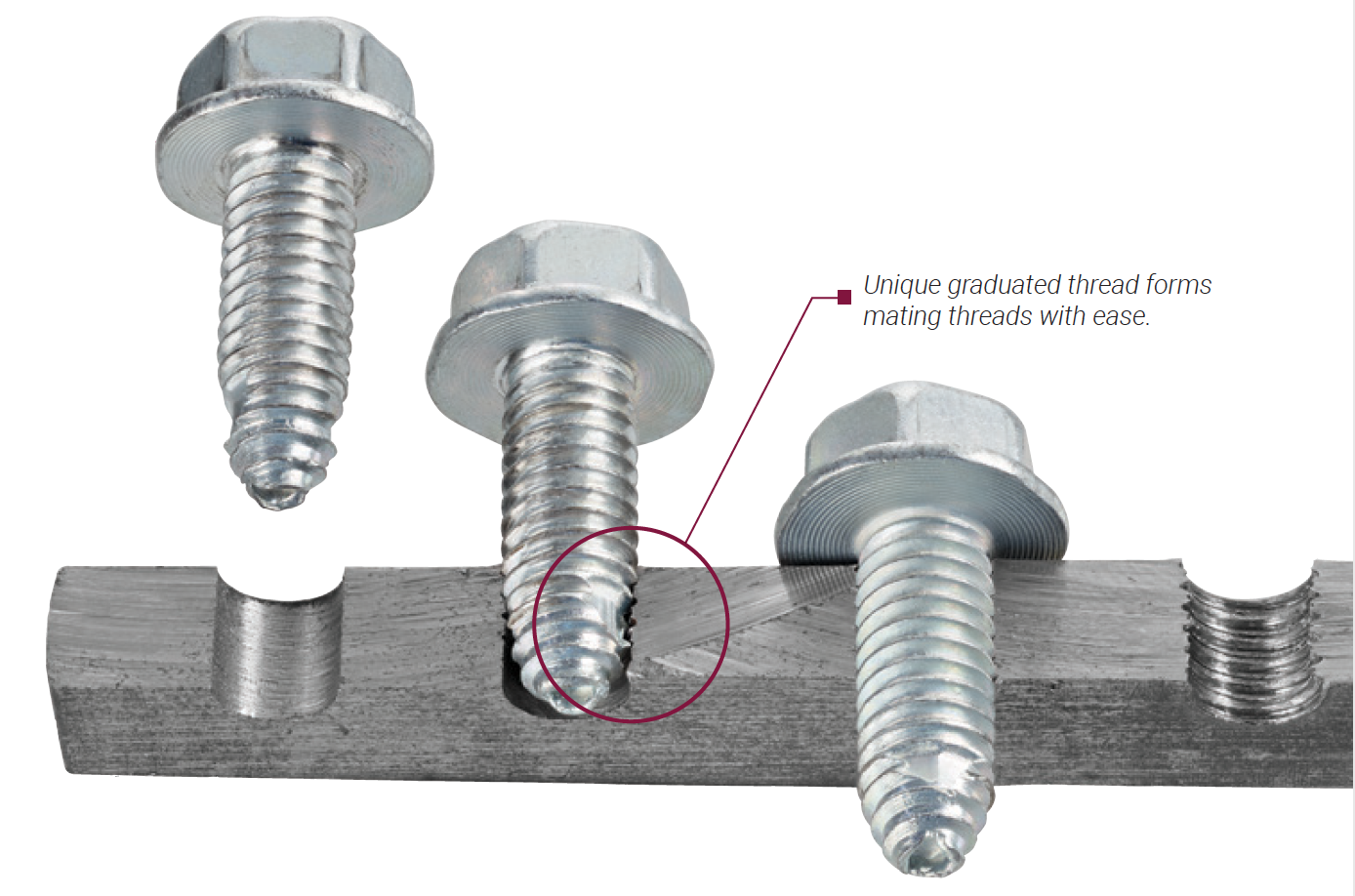

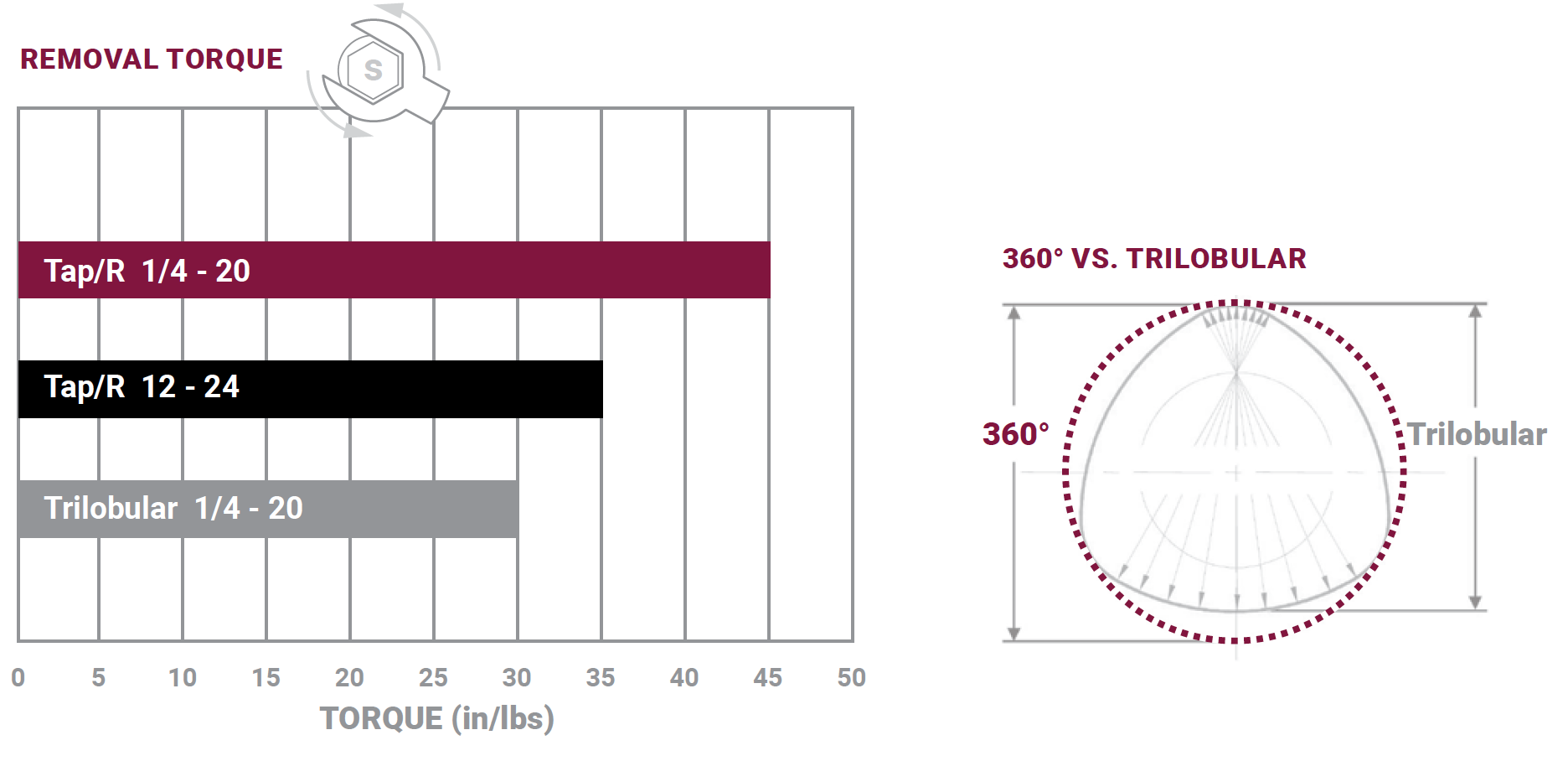

- ROUND SHANK ASSURES FULL 360° THREAD ENGAGEMENT for maximum holding power.

- RETAIN MORE APPLIED TORQUE AND CLAMP LOAD than tri-lobular type screws.

- RETAIN SAME HOLE SIZES as trilobular type screws. No need to change specifications or tooling.

- RAPIDLY LOCATE HOLES. Unthreaded relief area on point quickly positions screws in pilot holes.

- REUSABLE IN SAME HOLE WITHOUT CROSS THREADING. With its unique tapered, intermittent thread form, the TAP/R screw can be removed and reused in the same hole, time after time without damaging the mating thread.

- REMOVES PAINT AND PORCELAIN FROM HOLE. The relief areas on the two sides of the shank function as a paint scraper to remove paint or porcelain from the pilot hole.

- RELIABLE. CONSISTENT PERFORMANCE makes TAP/R screws ideal for automation qualified applications.

UNIQUE THREAD FORMATION STEADILY ROLL FORMS MATING THREADS:

-

- The TAP/R thread rolling screw consists of a unique thread arrangement that starts out as an intermittent, taper thread and increases to a complete 360° thread form.

- Unthreaded relief areas decrease friction during initial contact.

TAP/R SCREW POINT:

-

- The TAP/R screw has unthreaded relief areas that supply a positive lead into the pilot hole. At the start, the portion of the screw with intermittent threading only makes contact at the top of the out-of-round location. However, the mating thread undergoing roll forming and the screw shank achieve a 360° completely rounded and fully threaded configuration. Along with facilitating gradual roll forming, the tapered TAP/R screw point locates the hole. In the same way the special thread form also locates a previously created thread, the screw may be used in the same hole again and again with no cross threading.

EXPANDED SAFE RANGE OF OPERATION

GREATER TORQUE RETENTION:

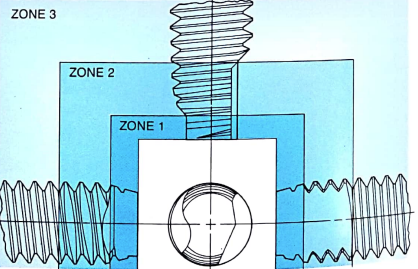

Zone 1: Consists of relief areas located on two sides of the shank. The process of roll forming commences when the apex’s intermittent thread contacts the workpiece.

Zone 2: One side of the shank accumulates partial threads while the other side remains unthreaded. These beginning threads consist of crests which add to the progressing shaping of the mating thread.

Zone 3: Consists of a full thread form on a complete 360° shank to supply complete engagement in the workpiece. This total engagement allows these thread roll forming fasteners to maintain a larger percentage of the tightening torque, and as a result, achieve a more secure hold than other thread forming screws.

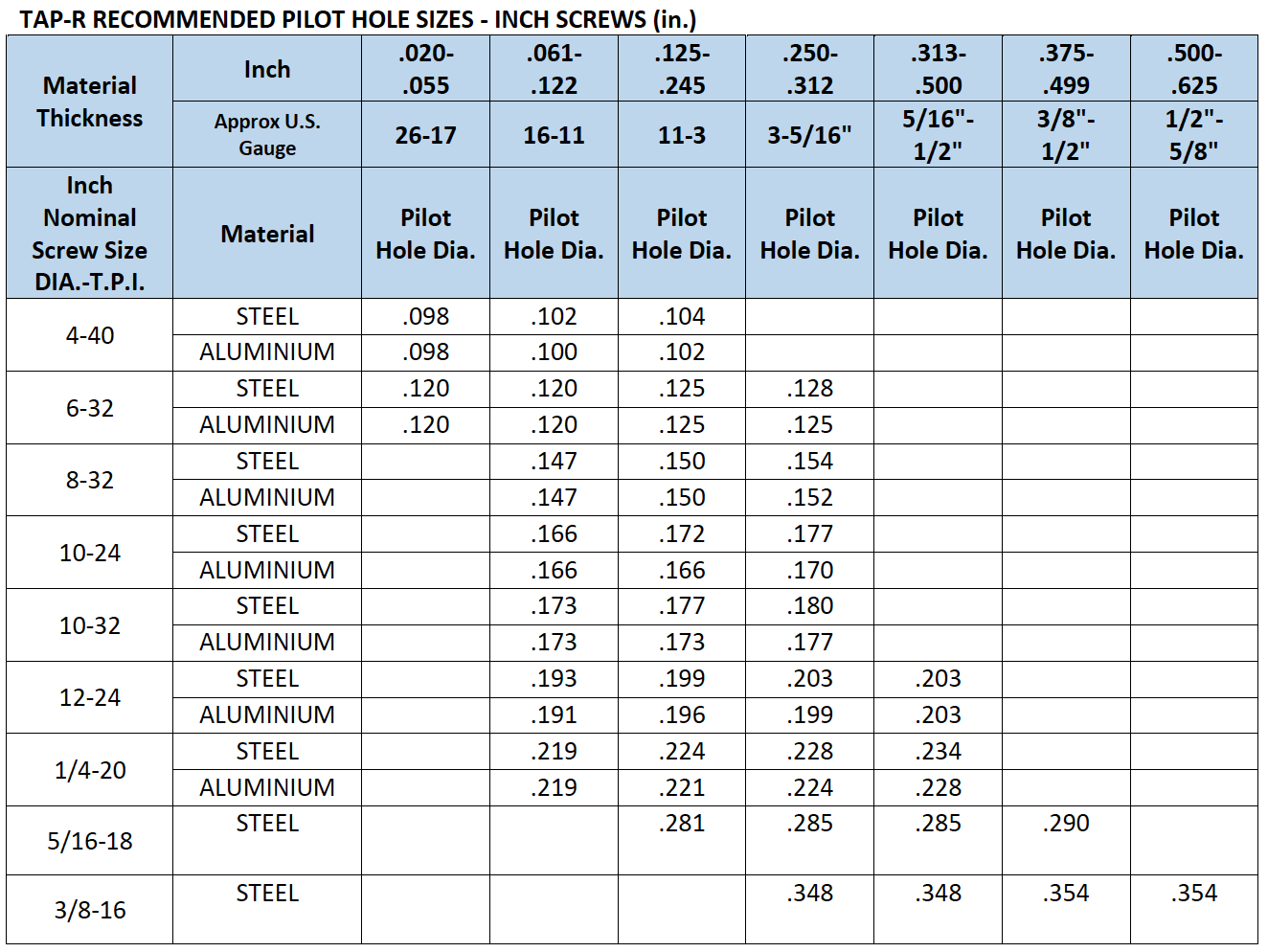

HOLE SIZE INFO